In lathe machining, there are three primary types of cutting tools: turning tools, boring tools, and parting tools. These tools serve distinct purposes and are crucial for various machining operations. Let's take a closer look at each type:

1. Turning Tools :

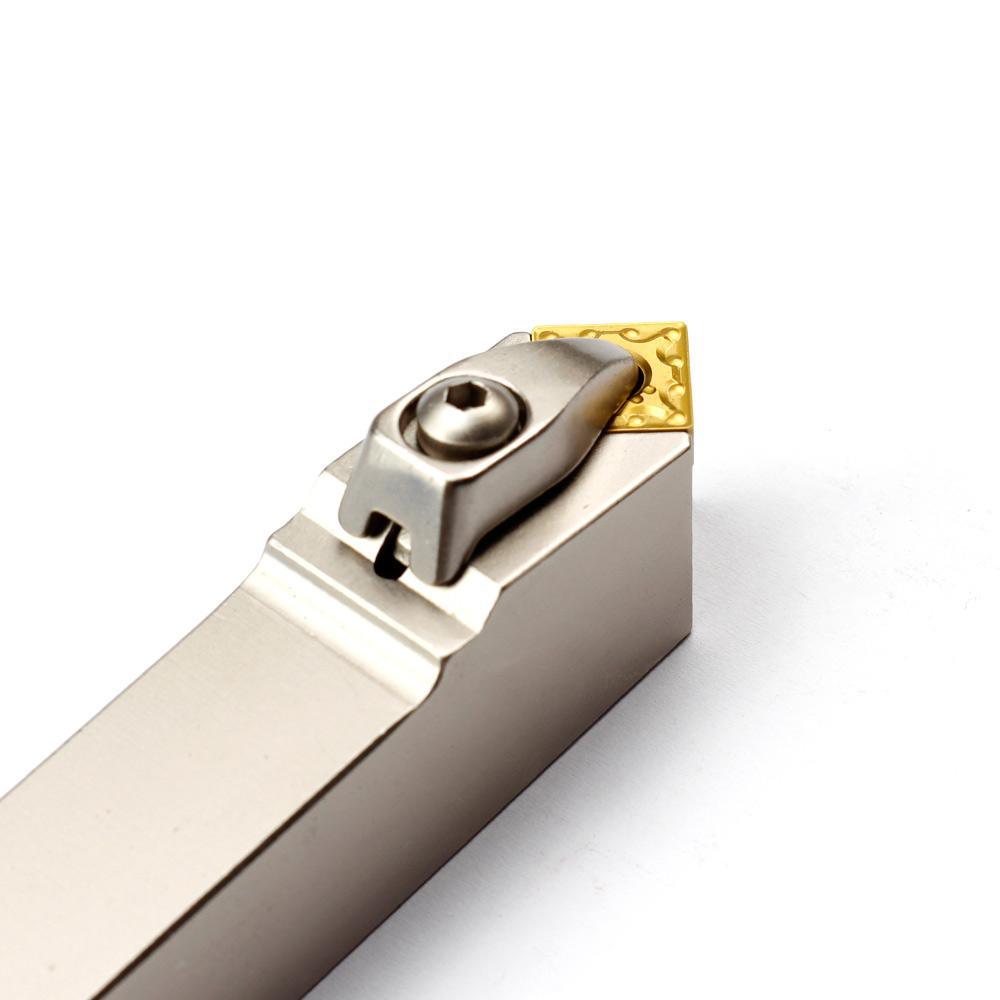

Turning tools are the most commonly used cutting tools in a lathe. They are designed for shaping the workpiece and creating cylindrical features. Turning tools typically have a cutting edge that is perpendicular to the axis of rotation. Here are three main types of turning tools:

a. Roughing Tool: The roughing tool is used for initial stock removal and quickly shaping the workpiece. It has a sturdy construction with a wide cutting edge, allowing for rapid material removal. Roughing tools are typically used at the beginning of the turning process to remove excess material and establish a rough shape.

b. Finishing Tool: Finishing tools have a narrower cutting edge and a more delicate construction compared to roughing tools. They are used for achieving a smooth surface finish, refining the shape of the workpiece, and adding final details. Finishing tools are typically used after roughing to create a refined, precise surface.

c. Parting Tool: Parting tools are used to cut off or separate the workpiece from the stock. They have a narrow cutting edge and are designed to create grooves, form shoulders, and produce tenons. Parting tools are particularly useful for creating precise cutoffs and establishing well-defined edges.

2. Boring Tools :

Boring tools are employed in lathe machining to enlarge existing holes, create internal features, or achieve precise diameter measurements. They are designed to remove material from the interior of the workpiece. Boring tools typically have a single-point cutting edge and come in various designs to accommodate different bore sizes and depths. Boring tools are used for operations such as creating cylindrical holes, countersinking, counterboring, and taper boring. They are particularly useful when machining internal features such as recesses, slots, or keyways.

3. Parting Tools:

Parting tools are specialized cutting tools used to separate the workpiece from the stock or create grooves and shoulders. They have a narrow, pointed blade and are primarily employed for cutting off or parting operations. Parting tools are designed to achieve accurate cuts and establish well-defined edges. Parting tools can also be used creatively to create decorative features such as beads, grooves, or flutes on the workpiece. They are essential for separating the finished piece from the stock or creating design elements that require precise cut-off points.

It's important to note that within each type of cutting tool, there are various designs and variations available to suit specific machining requirements. Additionally, specialized lathe tools exist for operations such as threading, grooving, chamfering, and facing. These tools complement the primary cutting tools and expand the capabilities of the lathe.

By utilizing different types of cutting tools in a lathe, machinists can perform a wide range of operations, including shaping, finishing, boring, and parting. Selecting the appropriate tool for the desired operation and maintaining their sharpness and condition are crucial for achieving accurate, high-quality results in lathe machining.